Metamaterials are usually identified by indicating it is a constructed material that has characteristics not observed in nature. As the last blog demonstrated, metamaterials at the nanoscale can be designed to work well in the optical and near-optical portion of the electromagnetic spectrum. There are also metamaterials that are on the millimeter scale. This blog will cover modification of sound waves with metamaterials.

A very generalized statement on metamaterials in the frequency domain is that it is possible to position material in such a manner as to inhibit the flow of the energy. As with the optical examples in the last few blogs, it is possible to create structures that act as if they have negative properties of the normal material. An interesting presentation [Ref. 1] provides a high level of various means of altering material properties in order to impact the acoustic (sound) waves.

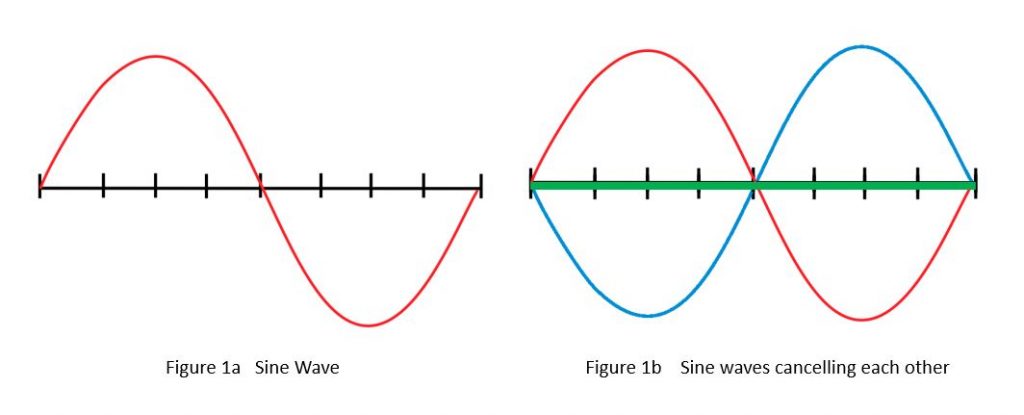

The function of the metamaterial to modify acoustic waves is created by developing geometries that create phase delays in portions of the wavefront that causes a cancellation of the wave front. Figure 1a depicts a sinusoidal wave in red. Figure 1b shows the addition of a second wavefront in blue that is precisely out of phase with the first wave. The net result is the straight green line that is the sum of the two waves. More details, including the mathematics involved, are presented in Reference 2.

So the question is “What can this type of device actually accomplish?” Typically, large and heavy materials are employed to mitigate noises. The typically “sound” barriers along the sides of expressways in the cities are a prime example of that approach. But, for individuals who need shielding working in a noisy environment, heavy and bulky is not a solution. Reference 3 presents work on a smaller, not large roadside structures, scale that was performed in Professor Xin Zhang’s Boston University’s lab.

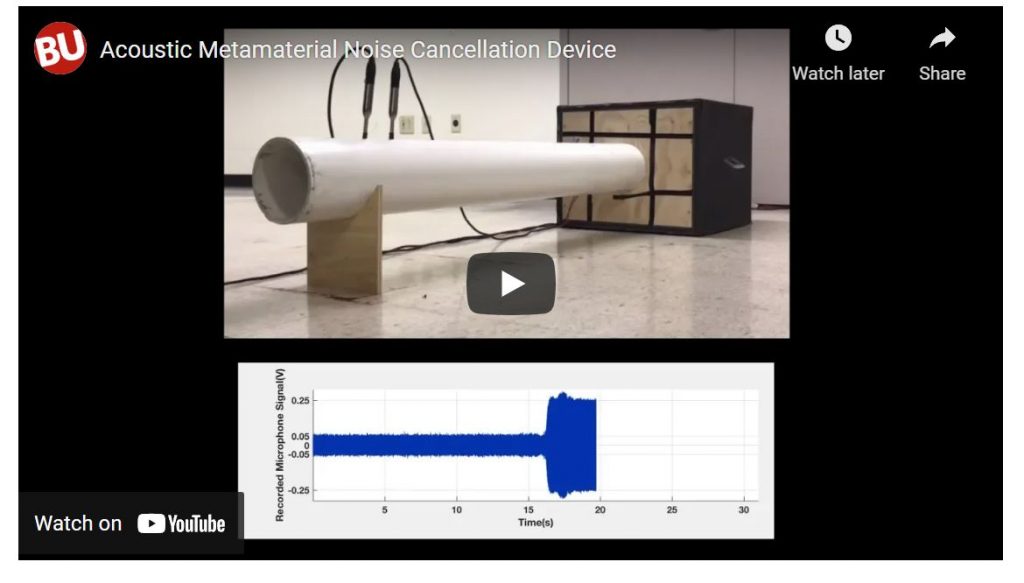

So, if one has the mathematics background and the computing power to calculate the desired structure shape, how do you prove it works. The researchers decided to create a structure that would cancel the sound from a loudspeaker. Figure 2 shown below is a picture of the experimental setup. The video link to its operation is Reference 4.

The bottom portion of the Figure 2 shows the sound exiting the plastic pipe and the increase in sound, shown by the larger blue area, is obvious when the acoustic silencer is removed. Their calculations indicate that they have reduced the noise level by 94%.

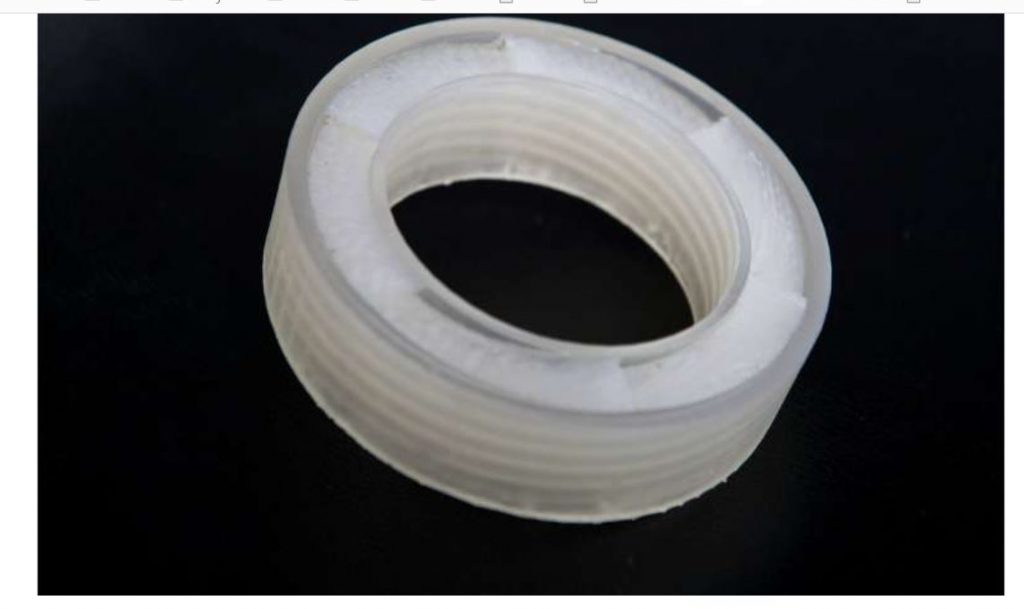

What does that acoustic “plug” look like. The picture below, Figure 3, is the plug, which is a 3D printed metamaterial, that modifies acoustic waves in the video in Figure 2 [Ref. 4].

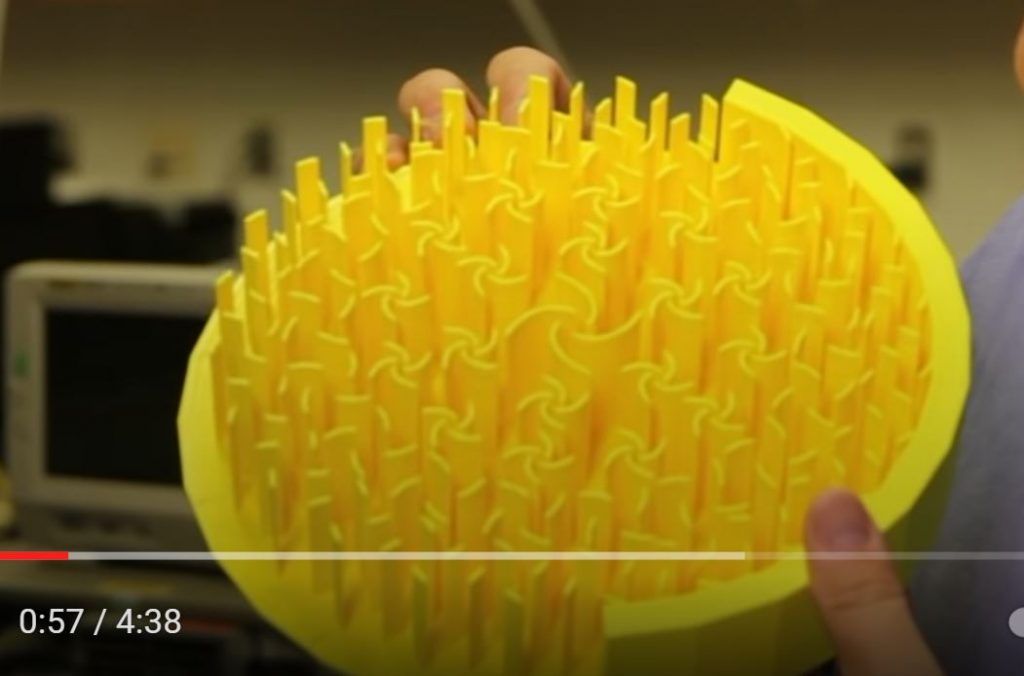

While this structure appears to be simple, the actual internal was not depicted in any of the articles on their work. In order to accomplish the sound cancelling, the structure is complex. There is a video from Duke University [Ref. 5] that provides an explanation of the modification of acoustic waves. Figure 4 below is a picture from the video in Reference 5 with the researchers describing how the different shapes and lengths impact the sound in order to modify it.

Obviously, the structure requires some serious design calculations. The ability to change the properties of sound waves with metamaterials that are large in size is due to the fact that sound waves have wavelengths measured in inches.

It is possible that these types of devices could replace the heavy sound blocking partitions along highways with lighter and possibly less costly specifically designed to reduce traffic noises while permitting more traditional neighborhood sounds.

References: